844

Swiss-made implants have earned a high reputation throughout the world due to their reliability and long service life.

The products of the Dental System company, which are manufactured taking into account the most innovative scientific and technical achievements, are no exception.

Now SGS implants are used in many domestic and foreign dentistry, because their main advantages include not only affordable cost, but also impeccable quality.

Who produces?

The Swiss organization SGS Dental System was founded in 2007 in the Principality of Liechtenstein. It is part of the SGS holding, a leading global leader in the certification, inspection and testing market .

This corporation includes more than 1,000 modern laboratories and offices, which are located in various parts of the world. Products manufactured by Dental System occupy leading positions in many countries in Europe, America and Asia.

Products are produced in Germany and Hungary. Recently, the company opened its own Medical Center, where training courses are held for dentists, and turnkey services for patient treatment are provided.

Production technology

SGS conical and screw implants are manufactured in Budapest, Hungary. For their production, biocompatible titanium alloys of Grade 5 and Grade 4 are used . The use of these materials virtually eliminates the possibility of structures being rejected.

The processing of Premium series products is carried out in Germany, in the DOT laboratory, which is equipped with equipment developed using the most modern technologies.

Here, a microcrystalline BONIT coating is applied to the structures, ensuring their biocompatibility and reliable fixation.

The process is carried out as follows: first, the products are cleaned in an ultrasonic bath, and then processed using the electrochemical method. After coating, all implants undergo a drying procedure.

Quality control of products is carried out by specialists at all stages of the production process - from the moment it begins to the very end.

How and where SGS implants are made

SGS Dental has been in existence for just over 10 years, so its production uses advanced and innovative equipment developed in recent years. It is almost completely automated; a mandatory step is computer modeling, which allows you to avoid inaccuracies in the process of manufacturing finished implants. According to the company, all products undergo the highest quality control, which is confirmed by numerous certificates - ISO, CE (European Certification Body) and NQA (National Quality Assurance System).

It is known that in recent years, SGS implants have been manufactured at production sites in different European countries. For example, surface treatment using the electrochemical deposition method takes place in laboratories in Germany, where the products are hermetically packaged. The products are then sent to the Hungarian logistics center located in Budapest, after which they are distributed to dealers. In Russia alone, the products of this brand are sold by 28 centers.

Advantages

products have many advantages over similar implantation systems:

- The structures have a high survival rate - up to 98%.

- All products have a unique double thread that allows for immediate load operations.

They are securely fixed at the initial stage, thanks to the increased gap between the wide turns. Strong fastening of the structures is carried out even with insufficient bone tissue. - The best tools and innovative equipment are used to produce implants. They are made from high-quality materials that guarantee their reliable fastening for a long time, as well as excellent biocompatibility with bone tissue.

- The products have a unique BONIT coating based on calcium and phosphorus, which creates a thin, uniform layer on their surface.

The coating has a high degree of solubility, prevents oxidation of the surface of structures, ensures their strong fastening, and also guarantees rapid engraftment and healing of tissues. - All products produced by the brand are certified.

- The products are produced in convenient sterile packaging.

- The structures can be attached at any angle, so they are especially recommended if there is a need to restore the entire dentition.

- The manufacturer offers a large selection of products that have different shapes and diameters from 3-6 mm.

The variety of assortment makes it easy to choose an option for each individual case. The company also produces various gum formers; straight and angular abutments with an angle of 15-45 C. - Swiss products are suitable for both two-stage and one-stage operations.

- Implants made of medical titanium completely restore the functionality of the dentofacial system, and also allow you to evenly distribute the chewing load.

- Products produced by the brand have identical functionality and can interact well with various dentures, gum formers and abutments.

- Installing implants allows you to significantly save money, since the operation does not require the use of a large number of structures.

For more information about the benefits of SGS implants, watch the video:

SGS brand overview – model range, advantages and disadvantages

Article navigation

- About the manufacturer

- Features of implants

- - shape and carving

- — material for implants

- - Premium surface

- — versatility of abutments

- — instruments and sterile packaging

- Types of implants

- - models P1 and P7 with internal hexagonal connection

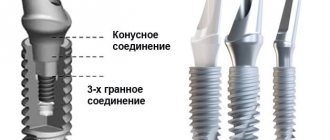

- - models P1D, P5D and P7D with conical connection

- - model P7N

- — monolithic models P7S and P9S

- Advantages

- Flaws

- How and where are they produced?

- Video about dental implants

- How are implants installed?

- Product Warranty

- Service life and care rules

- Cost of SGS implants

- Alternatives

- Reviews from real patients

Question for a specialist

SGS implants (the brand name is read as “SGS” or “SGS”) are developed by the Swiss company SGS International Ltd. in the SGS Dental Swiss Implant Systems division. They appeared on the Russian market around 2011, but during that period they received a fairly large number of negative reviews. Now the company has significantly improved the quality of its products, so doctors’ reviews of SGS implants from Switzerland have radically changed for the better.

Kinds

The company's official website presents four series of products.

In addition, the catalog contains :

- angular and straight abutments;

- temporary abutments made of durable polymer materials;

- adapters designed for crowns on implants that need to be attached at an angle;

- gum formers;

- instruments necessary for performing a surgical operation.

P7(Premium) Series

Thanks to the conical shape and double sharp thread, the implants have high performance characteristics. They are recommended for use for bone types 3 and 4 .

Self-screwing condensing-type structures are easily installed, preventing bone injury, do not interfere with its growth and can be well attached even in sparse bone tissue.

The unique shape of the products makes it possible to change the direction of insertion of the structure during the operation. A microcrystalline “Bonit” coating is applied to the surface of the implants, guaranteeing their rapid engraftment.

We’ll talk about what the price of basal dental implantation depends on in the next article.

In a separate article we will discuss which front teeth are best to insert.

At the link https://www.vash-dentist.ru/implantatsiya/metodiki/bazalnaya/pisanie-obzor-raznyih-proizvoditeley-tsenyi.html we have posted a review of BOI basal implants.

Series P1(Premium)

Screw-shaped designs are recommended primarily for installation in dense bone tissue, but they can be used in all types of bone .

The products have a double thread, which guarantees their reliable fixation even in difficult clinical situations. Good biocompatibility of implants is ensured by the biologically active “Bonit” coating.

These models are not recommended for immediate loading operations.

P9S series

Integral thin structures are designed for one-stage implantation. Conical products are suitable for use in narrow alveolar ridges and are also used for fixation between closely spaced permanent implants or teeth.

Models are not used for soft bone, they are recommended for installation in hard bone tissue . This option is well suited for immediate loading applications.

P7S series

Conical-shaped products are used for implantations with immediate loading, in case of sufficient bone tissue. These models have a fused structure, due to which they have a high level of strength.

They are quickly fixed and prevent the occurrence and development of infection during operation.

Implants are suitable for all types of bone , but they are not recommended for use in soft bone tissue.

How are implants installed?

Implantation of the SGS implantation systems can be carried out in the following ways:

- flap surgery: with gum detachment and bone tissue dissection. It is used for traditional two-stage implantation (when the load on the prosthesis is delayed for 4-6 months). The operation greatly injures the tissue, so the implantologist has to apply sutures, and tissue healing takes several weeks.

- minimally invasive method: or the puncture method - a small depression is made in the gums and bone, through which the implants are placed. The method is used in one-stage protocols with immediate loading of the prosthesis. Sutures are applied very rarely, because this method is gentle on the gums and bone tissue, which are restored in just a few days.

During implantation, emphasis is placed on the individual characteristics of patients - structures can be installed at almost any angle (from 90 to 45 degrees), which is especially important when restoring a large number of teeth using immediate loading methods and during atrophic tissue processes.

And do not forget that you must prepare for implantation - undergo tests in advance, undergo a computed tomography scan of the jaw, so that the doctor can choose the optimal treatment plan for a particular patient.

What determines the service life?

The average service life of implants made from high-quality titanium alloys is at least 25 years .

However, the durability of a product depends not only on its quality, but also on many other factors :

- condition of the patient’s bone and soft tissues;

- degree of load on the implant;

- quality of the operation performed;

- patient compliance with the dentist's recommendations.

In addition, it is necessary to strictly follow the rules for caring for implants :

- brush your teeth several times a day;

- rinse the mouth with special means;

- undergo regular preventive examinations at the dental clinic.

SGS implants can indeed last reliably for many years, especially if their initial implantation occurs without any complications.

If the patient has changes in bone tissue or the implants are regularly subjected to strong mechanical stress, over time, it may be necessary to replace them.

Official warranty period

SGS Dental System provides a lifetime warranty on all implants produced. However, the warranty is valid if the structures are used in accordance with the operating instructions that accompany them.

Features of SGS implants

When considering SGS implants from Switzerland, one cannot ignore their characteristics - after all, this is the main factor that directly affects the duration of operation. You can often find information that the survival rate of implant systems of this brand is 98% (which is a very high figure). However, for such a “young” manufacturer, which has been on the market for just over 10 years, it is still very early to provide current statistics - at least another 10 years must pass to understand whether the survival rate of SGS implants is really so high and corresponds to the world's leading manufacturers.

Let's look further at the factors that help SGS Dental Swiss Implant Systems ensure its implant products are competitive.

Shape and carving

All models from SGS have a root-shaped design - i.e. in the upper part the implant follows the shape of a cylinder, and in the lower part it smoothly turns into a cone. This form is physiological, because similar to natural root.

The thread comes in various options - it can be a little aggressive, or it can be not aggressive at all (i.e., the edges of the threads are either pointed or flat). Some models also have fine threads on the neck, which has a positive effect on the process of osseointegration (fusion of the implant with the bone) and maintaining a high level of marginal bone. That is, even several years after implantation, the gums under the crown will not take on a “bluish” tint, because the neck of the implant is almost not exposed.

Here it would be fair to note that so far there is no such implant in the world that, 10-20 years after implantation, would retain a sufficient level of marginal bone around its neck. There is always subsidence. But, for example, in premium brands (Nobel Biocare), the bone level decreases by only 0.3 mm in 10 years, and in representatives of the middle price segment, resorption of the edge of the alveolar process is 1-1.8 mm in the first 5 years.

Implant material

uses grade 5 titanium in production. This is a purified material that is biocompatible with the human body - titanium does not rust or release toxins. But still, grade 5 is not the purest titanium. It is known about titanium alloy Grade 5 that, in addition to titanium itself, the alloy contains 6% aluminum and 4% vanadium - these metals give the material special strength, exceeding the strength of grade 4 titanium by 3-3.5 times. And at the same time, Grade 5 titanium is cheaper than Grade 4.

Negative qualities include the effect of aluminum and vanadium ions, which is expressed in slowing down osseointegration. That is, such products will take longer to take root in the bone than the purest grade 4 titanium. However, in order to neutralize the negative features of the alloy, the manufacturer introduced a special surface that accelerates osseointegration.

Premium surface with active properties

SGS brand implants have a rough and microstructured Premium coating, patented under the abbreviation SBTC. Rough coatings are approximately 1.5 times larger than smooth surfaces in terms of contact area with bone tissue, which has a positive effect on secondary fixation of the implant.

Premium coating is obtained by electrochemical deposition of beta-tricalcium phosphate particles on the surface of the implant. As a result, a special hydrophilic relief is formed (saturated with phosphorus and calcium ions), into the structures of which blood cells quickly penetrate, fibrin protein filaments are attached - they serve as “paths” for the migration of young bone cells settling on the surface of the SBTC. Within 6-12 weeks after implantation, the surface layer of calcium phosphate, which is actively involved in osseointegration, dissolves and is replaced by young bone. Those. The implant is already held in the jaw not only by the threads, but is also completely “enclosed” by stable bone.

Abutment versatility

Each abutment from SGS fits any implant from the same manufacturer, which, according to dentists, simplifies the prosthetic procedure and solves even complex clinical situations. In addition to straight abutments, the company produces angular multi-unit abutments - their tops are located at an angle from 17 to 30 degrees. Such superstructures are indispensable when implants are implanted obliquely into the bone (when, for example, a patient experiences bone tissue atrophy due to long-term absence of teeth in the lateral parts of the dentition), as well as when dental crowns or dentures are fixed with screws rather than cement. The company produces abutments in the form of attachments (locks) used for fixing conditionally removable dentures.

As for the connection, implant-aba produces 3 options - internal hexagonal connection, internal cone and narrow cone (we will consider them below, in the section on implant models).

Instruments and sterile packaging

All stages of the production of implantation products undergo strict control to prevent errors and contamination of products. Each implant is supplied in individual sterile packaging and includes instructions. To facilitate the dentist’s work during implantation, the manufacturer produces several surgical kits with color-coded instruments.

Certificates

The products of the Swiss brand meet all international quality requirements. the CE mark by the European Union Certification Body , confirming its compliance with safety standards.

All dental products have ISO and UNI EN ISO certificates issued by the International Organization for Standardization.

These documents confirm the reliability and impeccable quality of the products. In addition, the company's activities are approved by the FDA, which exercises sanitary control over the quality of medical products in the United States.

We will tell you how Nobel Active implants stand out in a new publication.

In this article we will calculate how much it costs to insert a gold tooth.

Here https://www.vash-dentist.ru/implantatsiya/proizvoditeli/zubnyie-astra-tech-obzor-produktsii-kompanii.html you will find reviews about the effectiveness and reliability of Astra implants.

Price

The manufacturer produces several types of implants, the price of which depends on the characteristics of their thread, diameter and shape .

Let's take a closer look at the cost of the models offered by the brand:

| Implants | Price |

| Series P1(Premium) | 5000 rubles |

| P9S series | 5700 rubles |

| P7(Premium) Series | 4500 rubles |

| P7S series | 5700 rubles |

Reviews

Despite the fact that SGS implants appeared on the domestic market relatively recently, they have earned a lot of positive feedback from both patients and specialists working in dental clinics.

The structures are easy to take root, do not cause discomfort and are quite affordable.

You can share your feedback on the quality of Swiss products in the comments to this article.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags SGS implants implantation prosthetics

Did you like the article? stay tuned

Previous article

How to read a plot for toothache: who can benefit from home methods?

Next article

Smart Clip braces: reliability and efficiency from the manufacturer