When the need arises for prosthetics of one or more teeth on implants, the patient always faces a difficult choice - which implant to prefer, because today there are at least a couple of dozen brands on the market. Russian, Korean, Israeli, German, Swedish - for 10, 30, 80 thousand rubles...

Next we will talk about one of the most popular dental implantation systems – MIS from the Israeli company Medical Implant Technologies. A distinctive feature of MIS implants is their very affordable price, which largely determines the popularity of the brand among patients (and doctors) in Russia.

But do these implants have any more significant advantages than just a low price? And is it worth installing them at all, or is the low price in this case associated with a high risk of implant rejection and the development of other complications?

Let's find out...

A few words about the manufacturer

Medical Implants Technologies (MTS), which produces MIS implants, is based in Israel, but components for implant treatment are also developed in factories in France and Germany. Today, more than one million MIS implants are created per year using modern robotic equipment.

A dental clinic can buy MIS implants only from official representatives (in the Russian Federation, one of the main ones is, which has a dealer network almost throughout the country). For the uninitiated, this doesn’t mean much, but in reality this is a significant argument in favor of the Israeli company, since the patient in this case is quite reliably protected from the appearance of a fake implant of dubious quality in his mouth (yes, there are such on the market).

It is also worth noting that the company’s products are on the Russian market legally - they have all the necessary certificates and registration certificates. The manufacturer has also received certificates of product compliance with quality standards of the European Union and the USA - ISO and FDA (MIS implants are used in many European countries, as well as in the USA).

Quality standard

All Medical Implant Technologies Ltd factories have a multi-level quality control system.

The production of dental systems takes place on Japanese and Swiss laser control and measuring equipment, which is characterized by an ultra-precise measurement system.

The compliance of Mis implants with the requirements of international standards for medical products is confirmed by numerous certificates and registration certificates issued by such expert organizations as CE, FDA, ISO.

Technological advantages of MIS implants

Now let's look at what technological solutions are included in the design of MIS implants, because it is their combination that in many ways distinguishes a dental implant from a conventional metal (titanium) self-tapping screw.

On a note

In promotional materials for implants from different brands, even relatively minor differences from competitive products are often praised as revolutionary know-how. Next, we will try to describe the characteristics of MIS implants, primarily from the point of view of the benefits that they actually provide to the patient.

- Conical or cylindro-conical root-like shape. In other words, such implants have an anatomical shape, like the root of a natural tooth. This is important from the point of view of uniform distribution of the load on the bone and for successful osseointegration. At the same time, this form is not something unique, and is used in most other implantation systems - both economy class and premium implants;

- Double thread (well expressed, for example, in MIS Seven implants). This technology is a significant plus. It provides the effect of sufficient compression of bone tissue in the depths of the socket (that is, during installation, the bone compresses, forming a dense layer around the implant), and at the same time, microthreading in the area of marginal bone (near the gums) prevents bone tissue atrophy in this area over time . Simply put, the implant will be held quite firmly in the bone immediately after installation, and the effect of gum subsidence in the area of the installed implant will be minimized over time;

- Titanium alloy instead of pure titanium. Here it should be borne in mind that this is rather a minus than a plus. On the one hand, this allows you to significantly reduce the cost of implants and make them stronger. On the other hand, according to a number of studies, this can affect the likelihood of implant rejection and cause allergic reactions. Premium category implants are made from more expensive pure titanium - and that says a lot;

- Rough surface. Not so long ago this was a novelty, but today almost all companies produce classic dental implants with a porous surface (products undergo sandblasting with high-pressure abrasives or acid etching, or both types of processing sequentially). As a result, the titanium surface of the implant contains micropores into which growing jawbone cells penetrate - over time, the implant and the bone become one.

On a note

In March 2020, the EDI Journal published an independent study of implant surfaces from 62 manufacturers. Interestingly, for a long time there was no single standard according to which such an assessment could be carried out. But it is the outer part of the structures that comes into contact with the bone, and its contamination significantly increases the risk of tissue infection.

According to the mentioned study, many well-known companies (Nobel, Straumann, Friadent, Dentium) had microparticles of sulfates and silicon found on their surfaces. Implants of such brands as MIS (the SEVEN line was evaluated) and AstraTech turned out to be clean - no contaminants were found on their surface.

The researchers note that the chemical changes are not intentional, they occur during the final stage of treatment (jet or acid), but may increase the risk of peri-implantitis and implant failure.

- Individual packing. Each MIS implant is placed in a protective flask and box with a convenient tear-off tab for quick opening during surgery. This is a rather significant point, because it is important that the doctor opens the package in front of the patient, since this guarantees the sterility of the product and that it is the Israeli implant chosen by the patient that will be installed, and not a “no name” product. It is also important to have a serial number - it must be indicated in the patient’s record, which protects against counterfeit products and allows you to contact the company in the future to fulfill warranty obligations;

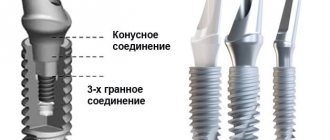

Among the technological features of MIS implants, noteworthy is also the presence of different types of connection between the implant and the abutment (that is, the tip on which the prosthesis is fixed). In the Israeli MIS system there are two types of implant-abutment connections:

- conical connection,

- internal hex connection.

It is also useful to read: Complications and problems that sometimes arise after dental implantation

The use of both types of element connections is justified and is also actively used by some other implant manufacturers.

The conical connection is more expensive. The lower part of the abutment is made in the form of a cone, inside the implant there is a recess of a similar shape. The connection occurs due to the forceful insertion of the abutment and its wedging on the implant platform. If you conduct an experiment outside the oral cavity - simply place the abutment in the implant and turn the structure over, then all the elements should remain in place.

Among the advantages of a conical connection:

- no gaps between elements, which reduces the risk of secondary infection and penetration of bacteria into the microcrack;

- the presence of a narrow “body” of the abutment, which allows restoration of even the front teeth, where aesthetics are most important (the crown will fit tightly to the gum).

Among the disadvantages is that sometimes difficulties arise during prosthetics (however, this does not affect the patient - the orthopedist and dental technician will have to work hard).

The internal hex connection is more common. It is very easy to use and is suitable for attaching any prosthesis. Among the disadvantages is the average level of tightness, which is why food debris and bacteria can get into micro-gaps.

As for the MIS implants themselves, there are several dozen modifications in their catalog, for almost any clinical case. For classical implantation, one-stage installation simultaneously with tooth extraction, orthodontic (for additional fixation of braces) and temporary implants. Thus, indications for treatment are the absence of one, several teeth, all teeth of the jaw, the presence of narrow and loose bone, the need to restore teeth immediately after removal, prosthetics with removable or permanent dentures.

Next, we will consider which MIS implants can be found in Russian clinics today.

MIS implant line

So, the MIS line of implants includes the following models:

- C1 is a modern root-shaped implant with a conical connection between the implant and abutment. It is used for classical two-stage implantation, as well as for implantation with immediate loading;

- Seven are universal root-shaped dental implants MIS with double threads, which improves bone compression during installation, as well as with microthreads (rings) on the top, which contributes to long-term preservation of bone volume in the gingival area. Suitable for almost all bone types. They are connected to a hexagon-shaped abutment;

- M4 BioCom is an implant with parallel walls up to the middle and tapering towards the lower apical part. The base is flat, which allows you to adjust the position of the implant directly during installation. M4 BioCom implants are used for any bone density, although they are more suitable for installation in soft bone;

- One-piece Uno implants are one-piece thin MIS implants in which the intraosseous part is inseparable from the abutment. They are used for both classical and implantation simultaneously with tooth extraction. Suitable for immediate loading (provided primary stability of the implant has been achieved). Ideal for narrow spaces limited by adjacent teeth, as well as for prosthetics of anterior teeth;

- Link orthodontic implants are small implants that are placed laterally. They are sometimes necessary for additional tension and fastening of braces when correcting bites;

- Temporary implants MIS - are installed into the bone without incisions or seams; they are necessary for the period of engraftment of permanent implants to support temporary removable dentures.

All of these implant models have different standard shapes, that is, they are suitable for short, normal or extremely narrow bones. From the point of view of an implantologist, a wide range of products is good, because if a complex clinical situation arises, there will be no need to turn to implants from another company; it will be possible to carry out treatment using the means of one implantation system.

It is also worth noting that Medical Implant Technologies is not limited to developing exclusively implants. The Israeli company produces a fairly wide range of products - these are not only MIS implants, but also osteoplastic materials (protective membranes and artificial bone for building), abutments (temporary, permanent, for removable and fixed dentures), plugs for implants, surgical instruments for implantation.

On a note

Before starting to work with MIS products, dentists undergo mandatory training from company representatives, upon completion of which they receive the appropriate certificate. For the patient, this is one of the guarantees that dental implantation will be successful and without complications, because the doctor will be professionally savvy.

See also the article Complications and problems that sometimes arise after dental implantation.

MIS implants - catalog of solutions for all cases

The official MIS website says that MIS Liment implants and orthopedic components are produced at a factory in Israel. Each implant produced by "Mis" (Israel) undergoes sandblasting and acid etching, which makes its surface similar in structure to natural bone tissue. Many MIS implants have a combined shape and an unusual thread pitch with special spiral-shaped tubules in the apical zone (at the tip). This concept is designed to provide primary stability during installation and optimal osseointegration.

MIS C1

The standard MIS implant is conical with a hexagonal connection and is designed to closely resemble the root of a natural tooth. Typically used for classic two-stage implantation, however, the manufacturer states that the C1 line can also be used with immediate loading (when a dental implant and temporary crown are installed during one visit).

MIS V3

One of the company's advanced developments. The implants of this series have a triangular coronal shape, which helps ensure the stability of the artificial root during installation and correctly distribute the pressure on the bone tissue. The design also allows for the preservation of the volume of soft tissue above the platform, which is why the installation of the MIS V3 implant often occurs for aesthetic restorations in the smile area. The diameter of the V3 series implants ranges from 3.30 to 5 millimeters, and the length - from 8 to 16 millimeters.

MIS SEVEN

These are self-tapping implants with double threads, the thickness of which increases from the tip to the neck. A universal system that is suitable for different types of bone, and is also installed during bone grafting. The shortest implants in this series are 6 millimeters long.

MIS M4

This series is a screw implant of a combined cylindrical-conical shape. Used for both two-stage and one-stage implantation techniques.

MIS UNO

A one-piece design that is designed specifically to replace missing incisors of the lower and upper jaws. Implants from this line are often used as a support for bridges.

MIS Link

This is a line of MIS orthodontic implants, which are not used in classical implantation, but are designed to perform a supporting function during orthodontic treatment.

Engraftment of implants: statistical data

More than one study has been conducted to determine the survival rate of Israeli implants. Moreover, both within the company (the company is naturally interested in improving the quality of its products and identifying emerging problems) and independent ones. The average result of engraftment of MIS implants is about 97%, and if the patient has periodontitis, it is 88%.

Below are some examples.

First study (duration – 5 years): 1954 patients were fitted with MIS implants (7340 in total). All participants had an X-ray examination six months after surgery or earlier if the patient smoked or suffered from bruxism (strong jaw clenching, usually at night) or he showed signs of peri-implantitis, that is, inflammation of the bone around the implant.

Results: engraftment percentage – 99.7%. In the first years, 21 implants failed, and after the installation of prostheses, another 18 failed.

Second study (over 4 years): MIS SEVEN implants (294 pieces) installed in 92 patients aged 27 to 71 years were evaluated. The majority had a lack of bone tissue; bone grafting was carried out simultaneously with the installation of implants. After the structures had healed (after 3-4 months on the lower jaw and 5-7 months on the upper jaw), prostheses were installed - single crowns, partial or complete dentures.

Results: The implant survival rate was 97.3%. In the first two years after installation, only 8 structures were removed; subsequently, no rejections were recorded.

This is interesting

The second study examines in some detail the relationship between implant failure and implant placement method. It has been proven that the method of implantation (classical protocol, installation with bone grafting or simultaneously with tooth extraction) does not have a significant impact on the quality of implant healing.

However, 5 of the 8 implants that did not take root were installed in the upper jaw while sinus lift surgery was performed. Moreover, 2 of them were rejected in a patient who had previously experienced failures during implantation.

Study 3: The healing quality of 262 MIS implants was assessed in 104 patients aged 17 to 77 years. More than half of the structures were installed in healthy bone (including in the socket of a newly extracted tooth), the rest were installed simultaneously with bone tissue growth.

It is also useful to read: Korean Snukon dental implants and their key features

Results: The average engraftment rate was 94.7%. On the lower jaw – 98.5%, on the upper jaw (with simultaneous sinus lifting) – 92.2%.

Fourth study: assessment of implant healing in patients with chronic gum disease (moderate and severe periodontitis). The study involved 19 patients aged from 34 to 79 years, who had 74 implants installed using the one-stage installation method, that is, immediately after tooth extraction. Only 12 MIS implants did not take root (they were replaced).

Results: The engraftment rate was 84%. If you have severe gum disease, this is a pretty good indicator.

Warranty and service life of implants

The manufacturer provides a relatively short warranty for the MIS implant system - only 5 years. However, the dental center itself where the implantation will be carried out will give a shorter guarantee - no more than 1-2 years (in fact, this is a guarantee for the doctor’s work). However, in practice, implants can last several decades. Naturally, subject to certain conditions.

How to make implants last for decades?

The conditions for implants to last not 5-6 years, but 15-30 years, are very simple: regular hygiene on the part of the patient is important. It is necessary to brush your teeth twice a day, rinse your mouth after eating, remove plaque from the enamel (even with artificial ones!), do not abuse solid food (do not crack nuts with your teeth) and be sure to visit a doctor at least once a year to monitor the condition of the implants (if suddenly problems have emerged - they are often easy to eliminate at the initial stage).

Don’t forget about maintaining the overall health of the body. Exacerbation of chronic diseases (cardiovascular, hormonal, immune) can lead to rejection of installed implants even with relatively good oral hygiene. In such cases, the “big” name, brand and cost of implants do not play a special role.

Remember that implants (even though they are maximally biocompatible) require increased attention, since they are surrounded by living tissues, serious inflammation of which can spoil the whole picture and lead to rejection of non-living material.

Reviews from doctors and patient opinions about MIS implants

The description of any implantation systems on paper can look very beautiful. But the main thing is how they behave in practice. And here it is worth noting a simple and telling point - Israeli MIS implants, both in Russia and abroad, have had one of the highest percentages of sales for many years.

If they were often rejected, then no “democratic” price would allow them to achieve such high popularity.

Implantologists who work with MIS implants speak very positively about the products and note the following advantages:

- ease of use - the kit includes all the necessary tools (keys, cutters, adapters) for installing implants. They allow you to create a hole for an implant quickly and without unnecessary loss of bone tissue;

- wide range – implant sizes start from 3 mm in diameter and 6 mm in length, so you can select designs for different types and volumes of the patient’s bone, solving almost any clinical problem;

- The MIS implantation system is highly compatible with abutments and instruments from other Israeli manufacturers - in practice, this means that the patient can go to another doctor, and even if the implantologist does not work with the MIS system, he will be able to complete the implantation he has started, correct or redo the work of his predecessor.

On the other hand, some implantologists note that MIS implants are not made of pure titanium, which increases the risk of rejection of structures and allergic reactions. In addition, the presence of a threaded neck is a relatively outdated technique, the use of which in some cases can lead to excessive plaque accumulation and gum inflammation.

However, for the most part, implantologists agree that in the competent hands of a doctor, both budget and premium models of implants are highly likely to serve the patient well for several decades.

Mis Dental Implants: Benefits and Features

Modern Israeli dental implants Mis are an opportunity to once again become the owner of a beautiful smile. Even where the teeth are very closely spaced, the screw type can be introduced completely unnoticed from the outside. In addition, the quality of the material is confirmed by the manufacturer’s warranty, which is issued for 5 years. Our dentists are ready to quickly and efficiently deliver Mis implants to every patient! Their main advantages are:

- Wide range of uses. The material is excellent for standard and immediate implantation in people with different volumes of bone tissue. Even when there is a shortage of it.

- A complex approach. The manufacturer specializes in the manufacture of special materials intended for bone regeneration or replacement, and also produces special devices for the most efficient surgical work. Our private business class clinic has all the necessary equipment.

- Modern technologies. The company has its own research institute and a number of clinical facilities. In addition, the manufacturer cooperates with world universities, which allows us to constantly develop and implement innovative technologies.

- High performance. Patients have been treated for 18 years in 72 countries. The company is included in the list of 10 best manufacturers worldwide.

If rejection occurs within five years after implementation, the clinic staff will exchange it for a new one free of charge. However, there is no serious cause for concern: the rejection rate is only 1%.

We are located on Kievskaya Street, next to the metro, and receive clients all day long without queues or discomfort. We have the best Israeli implants, including the most modern Alpha Bio, which are extremely popular.

Cost of dental prosthetics with Israeli MIS implants

As noted above, MIS dental implants are among the most affordable. The cost of installing one implant (excluding the cost of the prosthesis) will range from 15-18 thousand rubles, depending on the clinic. If we talk about turnkey implantation, the cost of treatment will be from 25 thousand rubles and more (will largely depend on the cost of the crown).

To summarize, we can say that MIS implants belong to the middle price category, they are actually created using a complex of modern technologies, and are characterized by a fairly high percentage of engraftment even in complex clinical cases. And what is important, they are common in clinics in Russia, that is, it will not be difficult to find a doctor who works with them.

An example of one-stage installation of an MIS implant (that is, immediately after tooth extraction)

What are the advantages

Among many implants, Mis has proven its quality and superiority. In a number of clinical cases, doctors recommend such systems to patients. The advantages of Mies dental implants are the following:

- a small list of contraindications for implantation;

- high quality metal alloy used in the production of products;

- sufficient strength of the rod part, which guarantees stable and reliable operation even under significant chewing loads;

- the possibility of installing implants in cases of severe bone tissue deficiency;

- a large selection of finished Mis products - this allows you to choose an implant for each patient.

The price of such implants is justified by their high quality. The manufacturer has tried to create a reliable design that is suitable for patients of all ages.