What are crowns needed for?

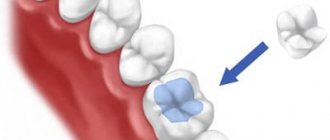

Many people wonder in what cases is it necessary to install a crown on a tooth? Crowns in dentistry are used only in cases where the destruction of the surfaces of chewing teeth is more than 50%. Indeed, with such depletion of the tooth walls, chewing loads lead to chipping of the tooth under the gum, which can lead to rather sad consequences.

A high-quality crown on a tooth will ensure adequate distribution of the chewing load and strengthen the teeth.

What types of crowns are there?

In modern dentistry, different types of crowns are used. They all differ in materials of manufacture and in their designs. Based on their designs, they are divided into 2 classes:

- supporting structures;

- restorative.

Based on materials of manufacture, they are:

- metal;

- metal-ceramic;

- porcelain;

- zirconium;

- metal-composite.

Support structures are used to restore chewing function. They are installed when all or several teeth are lost. They can be either temporary or permanent.

As for the manufacturing method, crowns can be:

- cast;

- stamped;

- combined.

Combined designs are considered the most common and in demand. They consist of a metal frame and a coating of ceramic, porcelain or composite. Stamped structures are cast from titanium, plastic or porcelain.

Solid crowns are made from the material chosen by the patient. Such designs are durable, practical and convenient. Due to their affordable cost, such designs are the most popular.

What are the types

There are several different types of artificial crowns. Depending on the purpose of these types of prostheses, they can be supporting or restorative. Support structures are used to subsequently secure the bridge. Restorative structures are required to eliminate existing hard tissue disorders. Depending on the material used, an artificial crown can be:

- metal;

- non-metallic;

- combined.

Non-metallic dentures are made of plastic or porcelain. For metal ones, alloys are used, and combined ones are made of metal, which is lined with porcelain or plastic.

Metal crowns are divided into stamped and cast. This classification is carried out taking into account the manufacturing method. Cast products are made by casting metal using pre-made molds. Stamped ones are obtained by stamping from special disks.

Advantages of metal-ceramic crowns

Metal-ceramic crowns, which are most often used in dentistry, have many advantages. The main ones include:

- reasonable cost;

- high quality;

- shape and color of natural teeth;

- durability.

Everyone knows that some people cannot install metal crowns. Firstly, they do not look very aesthetically pleasing. And secondly, some people simply experience allergic reactions. As for ceramic crowns, they are hypoallergenic and completely safe.

In the manufacture of such prostheses, only proven and high-quality materials are used. Such crowns are used if the tooth is severely damaged. It is also worth noting that such crowns, unlike metal ones, do not injure the gums and neighboring teeth. Also, such dentures are installed on chewing teeth, since they cope well with this function.

The service life of metal-ceramic implants is quite long. But again, it all depends on how correctly the crown was made, from what materials, and the like. Therefore, dentists strongly recommend visiting only proven and well-established dental centers with highly qualified specialists.

NeoStom – Dentistry website

Crowns and methods of their manufacture. The most common fixed dental prosthesis is an artificial crown (cap) that covers the coronal part of the tooth and follows its anatomical shape. When making fixed dentures, additional equipment is required. When stamping crowns, flattening pieces of metal, wire, etc. They use an anvil consisting of a body with processes that have the approximate shape of tooth crowns and a stand. To obtain plaster and metal crown stamps, rubber rings are used. Various hammers are used for stamping metal crowns. On the dental technician’s desktop there should be a set of special forceps (beak-shaped and contour), adapted for bending clasps and arches. The contoured appearance of the forceps helps to shape metal rings and crowns. To carry out stamping, it is necessary to have a massive, stable stand, which should resist shock well and absorb sound. For this purpose, a wooden stand is used. To melt metals and warm up metal sleeves for soldering, a dental technician needs a gasoline-powered soldering machine. Its main parts: • fuel tank; • gun-burner; • bellows or compressor. All 3 parts are connected to each other by rubber hoses. The gun is equipped with a flame regulator. In recent years, foot bellows have often been replaced by a compressor, and the gun (blowpipe) always remains the main part of the apparatus. The process of soldering metal prostheses, casting parts and etching them in acid is accompanied by the release of harmful gases. All these procedures must be carried out in a special fume hood with a fan, the walls of which are made of fire-resistant materials. Making crowns is indicated in the following cases:• to restore the destroyed coronal part of natural teeth in order to return them to full function and prevent the displacement of antagonists; • to restore the correct relationship of the dentition; • for fixation of fixed bridges; • to give teeth the shape required for fixing clasps in the manufacture of removable dentures, etc. It must be remembered that crowns have their advantages and disadvantages, so their use should not be abused. The downside is that when preparing a tooth, you have to grind off the hard tissues of the tooth, and the edge of the metal crown, to a greater or lesser extent, irritates the mucous membrane of the gums into the surrounding neck of the tooth. Complications more often occur in the case of insufficiently thorough preparation of the tooth or improper manufacturing of the crown. Errors made when modeling the chewing surface of the crown cause functional overload, which subsequently leads to loosening of the tooth covered with the crown and its antagonists. Wide crowns that do not fit tightly to the necks of the teeth can contribute to their destruction due to the development of caries. The correct manufacturing of the crown largely depends on the preparation of the tooth. It is known that the diameter of the tooth in the neck region is usually smaller than in the equator region. To ensure a tight fit of the metal crown, it is necessary to achieve a tight fit around the neck of the tooth. Convex parts of the tooth should not interfere with the fitting of the crown. To do this, they are pre-ground. The tooth prepared for making a crown must have a smooth surface, and its diameter should not exceed the diameter of the tooth neck. It is necessary that the chewing surface of the lateral teeth after preparation generally retains its relief. It is recommended to grind the palatal surface, the cutting edge of the front teeth and the chewing surface of the lateral teeth so that between them and the opposing teeth there remains a gap corresponding to the thickness of the metal of the future crown (0.3 mm) for steel and slightly more for gold, and not only in central occlusion , but also with all chewing movements of the lower jaw in relation to the upper. If this basic requirement is not met, artificial crowns will interfere with the smooth movements of the lower jaw. Such teeth will gradually become loose from excessive stress, and artificial crowns will wear out prematurely. The material for making crowns can be stainless steel, base metal alloys, gold-based alloys, palladium, plastic, ceramics and combinations thereof. Depending on the properties of structural materials, the technique for making crowns from one or another material differs in some features. Stainless steel is more difficult to stamp and requires knowledge of heat treatment rules. Heat treatment of gold is much simpler (it is enough to heat gold red-hot to restore its ductility). When heated, fewer oxides form on the gold surface. The melting point of gold is lower than the melting point of steel. The process of soldering gold parts of prosthetics is easier than steel ones, but working with gold requires attention and skill. If you work carelessly with gold, there is a danger of the prosthesis melting during soldering of its parts, and excessive thinning during polishing. When heated by the action of a low-melting alloy, gold is destroyed. After stamping, it is necessary to thoroughly clean the gold crowns from residual low-melting alloy by dissolving them in hydrochloric acid. Gold is softer than steel, so gold crowns are more easily abraded by antagonists. To prevent rapid abrasion of the gold crown, its chewing surface is thickened from the inside with solder. When preparing a tooth for a gold crown, hard tissues are ground off from the chewing surface, taking into account the intended filling. Solder is poured into the crowns after testing them in the mouth. It gives the crowns hardness, inflexibility and does not provide the opportunity to make corrections or, if necessary, re-stamp the crown.

For a crown made of porcelain or plastic, it is necessary to grind off a larger layer of hard tissue from all surfaces of the tooth, and when preparing a tooth for a combined crown (with a veneer of plastic or ceramic), it is necessary to remove a larger layer from its outer surface. Metal crowns are stamped, cast and combined. There are 3 main methods for producing stamped crowns : • external stamping (according to Parker); • stamping using the MGMSU method; • method of internal stamping (according to Sharp). The most common is the external stamping method.

You might be interested in:

- Crown according to Belkin

- Making a stamped crown

Advantages of metal composite crowns

Metal-composite crowns are made from a metal alloy and plastic. Their main advantages include low cost and attractive appearance. Such crowns hold tightly to the root of the tooth and do not allow harmful bacteria to reach it. The average service life of such a structure is 5-10 years. It is also worth noting that such structures retain the color of the cladding for a long time. Dental centers have a large selection of colors. Therefore, doctors will not have any difficulty in choosing the color of the implant exactly the same shade as your natural teeth.

Thanks to the development of modern technologies and the addition of special impurities, such implants differ:

- quite long service life;

- strength;

- good erasure coefficient;

- color stability.

Advantages of crowns made of metal-free ceramics

Due to its high strength and aesthetic appearance, this type of prosthetics is quite popular. The material used to make crowns is safe and harmless. People are not allergic to this material. As for the designs of metal-free crowns, they are:

- all-ceramic;

- all-zirconium;

- crowns based on a zirconium frame.

Crowns made of metal-free ceramics are incredibly successful where high-quality and professional dental restoration is required. Despite the fact that such implants appeared relatively recently, they have already taken a leading position in modern dentistry.

Types of crowns

It is really possible to get crowns on your teeth at a low price in Moscow. Of course, this depends on the model of the product and the number of teeth that need to be restored. If you plan to reconstruct a large number of teeth, you can install more affordable dentures. But implantologists advise combining different models. Thus, more expensive and aesthetic products are installed in the smile area, and crowns, which cost less, are placed on the back teeth.

Metal

Metal crowns are considered “last generation” prostheses. Their only advantage is cost and reliability. They can last for several decades, however, their aesthetic appearance immediately reveals the presence of a prosthesis, since in color and shape they do not have an external resemblance to a real tooth crown. It is for this reason that metal models are no longer popular today.

Metal ceramics

The most affordable cost of a crown per tooth is for metal-ceramic models. They are distinguished by their durability, as well as quite optimal aesthetics, relative to their cost. The main part of the prosthesis is made of high-quality metal, and on top it is covered with a ceramic layer, which allows you to achieve the effect of a natural crown. The price for installing a metal-ceramic crown on teeth is lower than for prosthetics with more modern models. This is explained by the imperfection of the product, which does not have the translucency inherent in real teeth. In addition, patients often have a gap at the junction of the crown and gum. Implantologists advise installing metal-ceramic prostheses in the back area of the jaw.

Metal-free ceramics

An alternative to metal crowns can be a prosthesis made of metal-free ceramics. The use of such products is recommended if the patient has an allergic reaction to metal. It is better to place dentures of this type on the teeth in the front row. Since they are made only from ceramics, they are not able to withstand heavy loads on the jaws, but high-quality models look like real teeth. The cost of dental crowns made of ceramics without metal impurities, despite their insufficient strength, is high, since aesthetic characteristics are often advantageous for patients.

Metal-plastic

If you want to put crowns on your teeth at an affordable price, but still get good functionality and aesthetics, experts recommend modern metal-plastic models. The base of the product is made from a durable alloy of cobalt and chromium. Only the crown is made of plastic. The advantages include their appearance. In addition to the natural shape, which can be identical to natural teeth, a thin layer of plastic allows you to create the desired translucency of the crown. However, these prostheses undergo deformation and discoloration over time, so they are more often used for temporary prosthetics.

Zirconium dioxide

The highest cost is for dental crowns made of zirconium dioxide. They are distinguished from prostheses made from other materials by their impeccable aesthetics, biocompatibility, increased strength and hypoallergenicity. They also have the advantage of a long service life. The production of crowns requires an individual approach, so the shade of the top coating is selected for the patient in accordance with the natural color of the enamel.

Installation of crowns on implants

Crowns for implants: the prices for which in our dental center are the most reasonable, and are considered more reliable than removable structures. In addition, they will not stand out among the teeth and will last much longer. But to install such an implant, it is necessary to carry out a number of preparatory work and firmly fix the crown.

Crowns on implants, the price of which is indicated in the clinic’s price list, are installed in cases where it was not possible to save the tooth root. In this case, prosthetics is performed with the installation of an implant. This procedure is much more complicated than simply installing a crown. But on the other hand, the patient will have an almost new full-fledged tooth, which will not be subject to caries and other diseases in the future.

Services of our clinic

Our dental center employs true professionals in their field. They know exactly how to choose the right crown, how to make it, and will do everything possible to make their patients happy.

Making crowns is a rather lengthy process. Various materials are used as the basis, such as titanium, platinum or gold. Next, porcelain is applied to the base. The result is an implant identical in color and shape to a natural tooth. It is worth noting that such crowns really are practically no different in appearance from real teeth. In addition, they are resistant to abrasion, aggressive dyes and various microorganisms.

In our clinic, dental prosthetics are performed at the highest level and in accordance with all standards. Our dentists will be able to not only make your smile beautiful and charming, but also restore all the functions of the lost tooth.

Removing dental crowns: reasons

The main reasons for removing dental crowns:

- planned replacement;

- violation of the integrity of the product;

- poor-quality materials or work, errors in design, which cause discomfort and pain;

- associated complications (prosthetic stomatitis, galvanic syndrome, caries of supporting units, allergic reactions to materials).

The leading specialists of the clinic "..." are pleased to offer a full range of high-quality dental services at affordable prices. The installation of metal-ceramic crowns and other types of prostheses is carried out using modern equipment using gentle anesthesia. Thanks to innovative methods of dental treatment and prosthetics, the restoration process will be painless and in a short time. We will return your snow-white smile. Trust the professionals!

Our doctors

Brodsky Sergey Evgenievich

Deputy Chief Physician, Candidate of Medical Sciences, specialties: dentistry and medical microbiology.

Work experience: since 1999.

Salatsky Dmitry Nikolaevich

Chief physician, orthopedic dentist, gnathologist, maxillofacial prosthetist.

Work experience: since 1988.

Shirinyan Sarkis Kimovich

Dentist, implant surgeon, orthopedist, therapist

Work experience: since 2000.

Skranzhevskaya Svetlana Vladimirovna

Hygienist, dental assistant

Work experience: since 1994

Seredin Evgeniy Vasilievich

Implant surgeon

Work experience: since 2004

Malanova Olga Andreevna

Dentist, orthodontist, therapist

Work experience: since 2020

Makarov Danila Vladislavovich

Dentist-therapist, endodontist

Work experience: since 2013

Molodtsov Dmitry Evgenievich

Osteopathic dentist

Work experience: since 1998

Artemyeva Oksana Alexandrovna

Orthopedic dentist, therapist

Work experience: since 2001