638

Modern dentistry is one of the areas that provides a request for the search and study of the properties of new materials for the manufacture of instruments and structures (pins, implants, crowns and dentures on implants) working in one of the most aggressive environments, which includes the human oral cavity.

Experts include titanium and alloys based on it among the most promising compositions that provide the necessary strength while simultaneously being resistant to corrosion.

The article is devoted to describing the specifics of use, choice of method and materials for producing titanium alloys with specified characteristics, used for the manufacture of dental structures and instruments.

Advantageous characteristics of the material

Titanium and alloys based on it have qualities that allow them to be used in the manufacture of a number of dental structures, namely:

- implants;

- pins;

- crowns;

- bridges;

- removable dentures.

Due to the technological and physical-mechanical characteristics of alloys based on this material, an optimal combination of two main qualities necessary for dental structures is observed:

- plastic;

- hardness.

Porous titanium and titanium nickelide have these two characteristics. They are used in the manufacture of implants because they have such quality as shape memory.

It has been proven that titanium alloys are preferable for the manufacture of implants for a number of reasons:

- The ability to passivate , that is, to form a special kind of film consisting of oxides. This film is inert, that is, it does not react with other substances.

- Low thermal conductivity.

- Possibility of connection and combination with other materials , for example, porcelain, dental composites.

- Simplicity of low tide technology. This quality applies to special alloys of titanium and nickel used in dentistry.

In the manufacture of crowns, the use of titanium provides a number of special advantages due to the following qualities:

- inertia, which reduces the risk of infection;

- low specific gravity, due to which the finished crown is light;

- elasticity;

- strength, thereby reducing the likelihood of abrasion.

When making removable dentures, titanium is preferable to other materials. The structures have the following characteristics:

- hypoallergenic;

- no toxic effects on the body;

- ease;

- strength;

- accuracy of reproduction of reliefs and surfaces in contact with tissues.

Removable dentures based on this material do not cause discomfort to the patient when used. Patients do not experience significant changes in diction or perception of taste.

Titanium and alloys based on it are high-quality materials that have a large number of advantages for the manufacture of dental structures.

Basics of guided bone regeneration and advantages of the technique.

Come here to learn more about the unique properties of the Cytoplast membrane.

At this address https://www.vash-dentist.ru/implantatsiya/metodiki/mikro-vector-tas.html we will talk about the purpose of Vector Tas microimplants.

Advantages

Alloys based on titanium have unique properties that allow them to be used for medical purposes. A variety of dental structures are made from titanium:

- implants;

- pins;

- crowns;

- bridges;

- removable dentures.

This metal has characteristics important for prosthetics. This is a plastic, lightweight and very durable material that does not oxidize in aggressive environments.

For dental purposes, titanium nickelide and porous titanium are most often used. These alloys are used in the manufacture of implants, as they have good shape memory.

When titanium is used for medical purposes, a thin oxide film is formed on it, protecting it from oxidation. The material has low thermal conductivity. It can be combined with porcelain and composite compounds used in dentistry.

It is easy and simple to cast structures of the desired shape from titanium alloy.

When using titanium in the process of making crowns, it is possible to obtain products with the following qualities:

Inertness to interaction with the external environment, due to which such structures have antimicrobial properties;

- elasticity;

- strength;

- durability;

- safety for the human body;

- hypoallergenic.

When using crowns or dentures, the patient's sense of taste does not change. The material does not have a toxic effect on the human body. The material can take any shape, repeating the relief of the teeth and the shape of the jaw. They do not cause discomfort when wearing dentures and do not change diction.

Unique properties and types of alloys

Titanium in dentistry is most often used in the form of alloys. Alloys based on this material with the addition of other elements give the resulting material special properties.

For the manufacture of dental structures, titanium alloys with such elements as:

- aluminum;

- chromium;

- molybdenum;

- nickel;

- tin;

- manganese;

- zirconium;

- copper;

- silicon;

- iron.

All of the additives listed above belong to three types of substances, each of which has a special effect on titanium:

- Alpha stabilizers. As part of the alloy, they stabilize the properties of the material. This group includes aluminum, oxygen and nitrogen. They increase the strength of the material by increasing the temperature during its transition to another phase.

- Neutral stabilizers. These include tin and zirconium. They increase the strength of the material without changing its properties.

- Beta stabilizers. These include all other elements used in the manufacture of the alloy, for example, copper, silicon, nickel. They increase the strength of the material by reducing the temperature during the transition to another phase.

The table below shows the brands of titanium alloys and their scope of application in dentistry.

| Alloy | Application |

| VT – 5 L | cast crowns, cast metal bases, bridges, splinting dentures, clasp dentures |

| VT - 6 | implants |

| VT1-00 | implants, removable dentures, metal-ceramic structures |

Each of the alloys listed in the table has special properties, which makes it the optimal material for the manufacture of a certain type of structure:

- The VT5L alloy contains aluminum. It gives the alloy strength and elasticity. It lends itself well to forging, stamping and casting.

- Alloy VT-6 consists of titanium, aluminum and vanadium. These elements give the material strength and ductility. It is less prone to corrosion than others.

- Alloy VT1-00 is made of titanium and iron. It is characterized by high ductility.

Depending on the combination of elements in the alloy, it becomes applicable for the manufacture of various types of dental structures.

Metal In Dentistry-Dental Alloys

Metal occupies a central place among materials in dentistry. Most fixed dentures and removable denture frames are cast (or stamped) from dental alloys. Alloys in dentistry are used as auxiliary materials for soldering and stamping. Dental instruments are made from them.

Article outline:

- Classification of metals and alloys in dentistry

- Structural metal alloys in orthopedic dentistry

- Noble metal alloys in dentistry

- Base alloys in orthopedic dentistry

- Auxiliary metal alloys in dentistry

Metals and alloys in dentistry Classification

All metals and alloys are divided into ferrous and non-ferrous.

Ferrous metals are iron and alloys based on it. Steel and cast iron. Cast iron contains more than 2.14% carbon. Not used in dentistry.

The surface of cast iron is matte and non-shiny. It is difficult to polish.

Steel in dentistry

an iron-based alloy containing less than 2.14% carbon. In addition to iron and carbon, steel also contains other metals. They give the alloy new properties (alloy steel), including making it stainless.

Steel copings for stamping crowns

Alloy steel is an alloy of iron and carbon, with the addition of any other metals. They change the properties of the alloy (melting point, hardness, ductility, malleability, etc.).

Alloy steel

Stainless steel is corrosion resistant steel. Chromium (21%), as well as other metals, are most often used as an anti-corrosion agent.

Non-ferrous metals are, respectively, all other metals.

Metals in orthopedic dentistry are divided into noble and non-noble

Noble metals (or precious metals) are metals that are resistant to corrosion and chemically inert. The main noble metals are gold, silver, and platinum group metals (platinum, palladium, iridium, osmium, etc.).

Base metals are metals that corrode easily and are not found in nature in their pure form. They are always mined from ores.

Depending on density

metals used in dentistry are light and heavy

There is no single point of view on this issue. The most general criterion is that the density of the metal is greater than the density of iron (8 g/cm³) or the atomic weight is greater than 50 amu. If at least one condition is met, the metal is heavy.

For ecology and medicine, heavy metals are metals that are highly toxic and environmentally significant. Which creates even more confusion. For example, gold with a density of 19.32 g/cm³ and an atomic weight of 197 amu. is not classified as a heavy metal due to its inertness and excellent biocompatibility.

According to their intended purpose, metal alloys in orthopedic dentistry are divided into:

- A. Structural – dentures are made from them.

- B. Alloys for filling – amalgams.

- B. Alloys for the manufacture of dental instruments.

- G. Auxiliary. Metals used for other purposes (For example, low-melting metals for stamping or solders).

According to the chemical composition, alloys used in dentistry are:

- Precious metal alloys

- Base metal alloys

Noble metals in dentistry and alloys

Noble metals in dentistry are expensive. But despite this, they continue to be used due to their excellent biocompatibility. They are not subject to corrosion, do not react with saliva, and do not cause allergies or intoxication.

A gold alloy may often be the only option for patients with polyetiological contact allergies.

Noble alloys are durable. Their only drawback (besides the price) is their softness and susceptibility to abrasion.

Gold alloys in dentistry

- 900-carat gold alloy. (ZlSrM-900-40).

COMPOSITION: 90% gold, 4% silver, 6% copper.

PROPERTIES: melting point 1063°C.

The alloy is characterized by ductility and can be easily machined under pressure (stamping, rolling, forging).

Due to its low hardness, the alloy wears off easily. Therefore, when making stamped crowns, solder is poured from the inside, onto the chewing surface or cutting edge.

Produced: in the form of disks with a diameter of 18, 20, 23, 25 mm and blocks of 5 g.

Application: for stamped crowns and bridges made of

alloy of precious metals in orthopedic dentistry

- 750 gold alloy (ZlSrPlM-750-80)

Consists of Gold – 75%, Silver and copper 8% each, and Platinum – 9%

Platinum gives this alloy elasticity and reduces shrinkage during casting.

Used for the manufacture of cast gold parts of clasp dentures, clasps and inlays

- Dental gold alloy 750 standard (ZlSrKdM)

Cadmium is added to the composition - 5-12%.

Due to cadmium, the melting point of the alloy is reduced to 800 C. (The average melting point of gold alloys is 950-1050 C.) Which allows this alloy to be used as solder.

Silver-palladium alloy in dentistry

Silver-palladium alloys are distinguished by a higher melting point = 1100-1200 C. Their physical and mechanical properties are similar to gold alloys. But corrosion resistance is lower. (Silver darkens when in contact with sulfur compounds) Alloys are ductile and malleable. Soldered with gold solder (ZlSrKdM).

COMPOSITION: 75.1% silver, 24.5% palladium, some alloying metals (zinc, copper, gold).

Used for stamped crowns. They are produced respectively in the form of disks of various diameters (18, 20, 23, 25 mm) and 0.3 mm thick.

Composition: 78% silver, 18.5% palladium, other metals.

Used as an alloy for casting in dentistry

The amount of palladium was reduced to 14.5%, silver was increased.

Used for tabs.

Base metal alloys used in orthopedic dentistry

To reduce the cost of prosthetics, alloys based on cheaper metals were developed to replace expensive gold.

In the USSR, cheap stainless steel was most widely used.

Today, the bulk of the market is occupied by cobalt-chromium and nickel-chromium alloys.

Dental stainless steel alloy - dental steel

Steel is the most common alloy in the world. Its properties are well known. And due to alloying agents, it can be given any desired properties.

Dental steel is very cheap.

Among the disadvantages: steel is heavy (density about 8 g/cm3) and chemically active. May cause allergies, galvanosis.

Dental alloy for crowns COMPOSITION:

1.1% carbon; 9% nickel;18% chromium; 2% manganese, 0.35% titanium, 1.0% silicon, the rest is iron.

Used for fixed prostheses: individual crowns, cast teeth, facets.

COMPOSITION: 0.20% carbon, 9% nickel, 18% chromium, 2.0% manganese, 1.0% titanium, 1.0% silicon, the rest is iron.

The following are produced from this type of steel in the factory:

- standard sleeves used for the production of stamped crowns;

- clasp blanks (for ChSPP)

- elastic metal matrices for filling, as well as separation strips

COMPOSITION: 0.25% carbon, 10.0% nickel, 18.0% chromium, 2.0% manganese, 1.8% silicon, the rest is iron.

APPLICATION: manufactured in the factory:

- teeth (lateral upper and lower) for stamped-soldered bridges;

- frames for metal-plastic bridges, for cladding;

- orthodontic wire with a diameter of 0.6 to 2.0 mm (step 0.2 mm).

Silver solder PSR-37 or Cetrina solder is used as solder for non-precious alloys.

Contains silver - 37%, copper - 50%, Manganese - 8-9%, Zinc - 5-6%

Melting point – 725-810 C

(cobalt-chromium alloy, cobalt-chromium alloy)

COMPOUND:

- cobalt 66-67%, alloy base, hard, durable and light metal.

- chromium 26-30%, introduced mainly (as in steel) to increase corrosion resistance.

- nickel 3-5%, increases ductility, malleability, toughness of the alloy, improves the technological properties of the alloy.

- molybdenum 4-5.5%, increases the strength of the alloy.

- manganese 0.5%, which increases strength and casting quality, lowers the melting point, and helps remove toxic sulfur compounds from the alloy.

- carbon 0.2%, reduces the melting point and improves the fluidity of the alloy.

- silicon 0.5%, improves the quality of castings, increases the fluidity of the alloy.

- iron 0.5%, increases fluidity, improves casting quality.

PROPERTIES of KHS dental alloy:

It is distinguished by good physical and mechanical properties, low density (and, accordingly, the weight of restorations) and excellent fluidity, allowing the casting of openwork products of high strength.

Melting point is 1458 C

The alloy is resistant to abrasion and retains a mirror-like shine for a long time.

Cobalt-chrome alloy in dentistry

Used for cast crowns, bridges, solid clasp dentures, frames of metal-ceramic dentures, removable dentures with cast bases, splinting devices, cast clasps.

Metal-ceramics metal composition in dentistry

Cellite-K – cobalt-chromium

metal alloy

metal ceramics in dentistry.

Nickel-chromium alloys in dentistry

Alloys in which the main element is Ni. The elements of this alloy, in addition to nickel, are Cr (at least 20%), Co and molybdenum (Mo) (4%).

The properties of the nickel alloy are close to the cobalt alloy.

Used: for casting fixed dentures and removable denture frames.

Today, the use of nickel alloys is limited due to their high allergenicity.

Titanium alloys in orthopedic dentistry

In dentistry, both pure titanium (99.5%) and its alloys are used.

Pure titanium

Alloys of titanium, aluminum and vanadium (90-6-4%, respectively) are used for casting and milling. And an alloy of titanium with aluminum and niobium (87-6-7%).

Titanium alloys are lightweight and surprisingly strong. But they are refractory and difficult to process.

In orthodontics, alloys of titanium, vanadium and aluminum (75-15-10%) are used to make arches.

Metals used in orthopedic dentistry

Nickel and titanium alloy – titanium nickelide – nickel 55%, titanium 45%.

The alloy has shape memory. Deformed cooled products made from this alloy return to their original shape when heated.

The alloy is used in orthodontics, where it takes the desired shape under the influence of body temperature.

It is also used to make endodontic instruments with shape memory.

Auxiliary alloys used in orthopedic dentistry

Bronze is an alloy of copper and tin. Aluminum bronze (aluminum instead of tin) is used in dentistry. It is used to make ligatures for splinting jaw fractures.

Brass is an alloy of copper and zinc; pins for collapsible models are made from it.

Magnalium is an alloy of aluminum and magnesium; aircraft parts are made from it (the alloy is very light and durable). In dentistry, articulators and some cuvettes are made from it.

Amalgams are an alloy of metal and mercury. Used for filling.

The topic is too broad; amalgam in dentistry will be discussed in a separate article.

Low-melting alloys in orthopedic dentistry

Low-melting alloys (Mellota, Wood, Rose) - contain Bismuth, Tin, Lead

– their melting point is about 70 C.

They are used for dies when stamping crowns, counter dies, and making collapsible models.

Low-melting metals in dentistry

Wood's alloy.

Melting point 68 C.

Composition: Bismuth – 50%, Lead – 25%, Tin – 12.5%, Cadmium – 12.5%.

Toxic because it contains cadmium.

Mellot alloy.

Melting point 63 C

Composition: Bismuth – 50%, Lead – 20%, Tin – 30%.

Rose alloy for dentistry

Melting point 94 C.

Composition: Bismuth – 50%, Lead and Tin 25% each.

Steel for dental instruments

Tool steel – contains carbon from 0.7% or more.

It is characterized by high strength and hardness (after special temperature treatment).

The addition of tungsten, molybdenum, vanadium and chromium to steel makes the steel capable of cutting well at high speeds. This steel is used for burs and cutters.

Tungsten carbide is not an alloy. A chemical compound of tungsten with carbon (chemical formula WC). Comparable in hardness to diamond. Used for the production of armor-piercing tank shells. And also for carbide dental burs.

Zirconium metal in dentistry

Zirconium dioxide is also not an alloy. Chemical compound of zirconium metal with oxygen. Its chemical nature is similar to ceramics, but it is harder and more durable. In dentistry they are used for the manufacture of milled dentures.

Metal alloys used in dentistry (conclusion)

It is impossible to imagine modern dentistry without metals. They are at the core of everything. And there is no material that can replace metal.

Processing technique

Titanium, used for dental purposes, has special properties, therefore, in the manufacture of structures, special rules for its processing must be applied.

When processing this material, the following parameters must be taken into account:

- physical properties;

- oxidation phases;

- structural features of the crystal lattice.

To process this type of material, special cutters are used. They have a cross-shaped notch.

When using them, the following conditions must be observed:

- reduced impact angle;

- reduced pressure force on the cutter;

- cooling the cutter during operation.

If the technology and processing rules are violated, the material undergoes a number of changes. The titanium product changes color and the surface becomes rough. Chips may form on the surface of the product. Defects of this kind are unacceptable for the manufacture of dental structures.

Material processing includes two main processes:

- Manufacturing of the product. For this purpose, special cutters are used. In the manufacture of clasp dentures or frames, carborundum discs and stones are used. The sandblasting method is also used.

- Sanding and polishing the product. For this purpose, special rotating rubber heads are used. To reduce the likelihood of surface damage, various types of polishing pastes are additionally used during grinding.

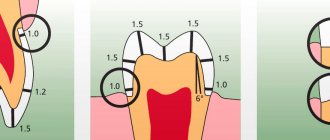

When working with a material such as titanium, special parameters have been developed. When working with a cutter, the following requirements are observed:

- low rotation speed;

- working in one direction only;

- smoothing sharp corners;

- periodic cleaning of the cutter.

When carrying out sandblasting, the following parameters must be observed:

- use of disposable aluminum oxide;

- use of fine-grained sand;

- the direction of the jet is at right angles.

After the treatment, the product is left for several minutes for passivation, that is, for the formation of a film of their oxides on the surface. After this, the product is cleaned with steam.

Special requirements are also imposed on the care of instruments.

- Tools used for processing and polishing titanium are stored separately from others.

- Instruments are subject to periodic cleaning. During operation, the cutter is cleaned with special brushes. After work they are cleaned by sandblasting.

In the manufacture of dental structures from titanium alloys, special methods are used. The work process proceeds in compliance with all requirements and standards.

Manufacturing of structures

Various techniques are used in the manufacture of prostheses from titanium alloys. Each method has a number of advantages and techniques for carrying out work.

Casting method

Using this method, individual crowns and bridges are made. The process includes several stages.

- Impression of the patient's jaws.

- Preparation of the casting mold.

- Making a working model of the prosthesis.

- Fitting and polishing the structure.

- Installation of surface coating made of ceramic or plastic.

This method is suitable for replacing one tooth, for example a molar, or several teeth.

Stamping

This method of making dentures is not used so often in modern dentistry because it is considered outdated.

Stamping of dentures consists of several stages:

- Making a plaster model.

- Modeling using dental wax.

- Making a metal stamp that follows the shape of a tooth.

- Selection of a titanium alloy sleeve.

- Stamping the sleeve according to the shape of the die.

In the manufacture of prostheses using this method, hot stamping is used.

How Bio-Oss bone material works and indications for its use.

In this publication, we will consider the advantages of implantation immediately after tooth extraction.

Here https://www.vash-dentist.ru/implantatsiya/metodiki/o-prieme-antibiotikov-posle-zubov.html we will tell you how much antibiotics you need to take after dental implantation.

Plastic molding

When using this method, work is carried out as follows:

- making a cast of the jaw;

- matrix production;

- adjustment of the sheet blank to the shape of the matrix.

This method is a simple technology that allows you to create a design accurately and quickly.

cad/cam system

The abbreviations CAD/CAM are English abbreviations and translate as “computer-assisted manufacturing.”

This method involves the following stages of work:

- making a cast;

- preparing a plaster model;

- scanning the model, building a three-dimensional model using computer technology;

- programming;

- automated processing of the prosthesis on a machine.

The production of an alloy prosthesis occurs under computer control, which eliminates inaccuracies or errors.

3D printing method

The product is made using a special printer, the operating principle of which is that the metal is applied to the model in the form of a powder in several layers.

Welding occurs using a laser. During the layering process, the required prosthesis of a given shape is produced.

The work process is controlled using a computer program, so the likelihood of inaccuracies is minimized.

In the video, a specialist talks about the advantages of titanium and its alloys.

Russian scientists have made titanium elastic, like human bones

The most important feature of the new alloys is their greater elasticity.

Researchers from the National Research Technological University MISiS, together with colleagues from Canada, have created an alloy with such high elasticity that for the first time it can be used as a full-fledged replacement for bones. An article about this was published in Materials Science and Engineering: A.

In the 20th century, scientists found that our bones break and crack so often mainly due to low physical activity. This became especially obvious during long flights into space, where without gravity, the muscles practically do not load the bones and they rapidly degrade. As modern lifestyles result in less and less physical activity, the strength of human bones will continue to decline, especially in old age. The number of fractures will increase. This means that a material is needed that can serve as a replacement for damaged bones.

The authors of the new work proposed several alloys based on titanium, zirconium and niobium for this purpose. All three metals are extremely resistant to corrosion, which is especially important because the human body is an aggressive environment where most metal parts are quickly destroyed. In addition, they are not toxic, like a number of alloying additives for steels.

The created titanium-zirconium-niobium alloys have “shape memory”. This means that when heated, they restore their original shape, even if they were completely crushed before. This property is very useful for implants: in the human body they constantly remain warm, which encourages the material to return to its original form. This prevents metal bone substitutes from deforming over time.

The most important feature of the new alloys was their greater elasticity. The fact is that before this, titanium alloys had already been used as replacements for damaged bones, but they had an unpleasant feature. Being strong as bone, but not very elastic, they did not transfer the load to the neighboring human bones. Those, without experiencing load, became less strong over time, and the connection with the titanium “bone” eventually turned out to be fragile. The titanium substitute began to “dangle” at the junction with the real bone, which endangered the patient’s health. With the new alloy, this problem will be solved - it will transfer the load to neighboring bones, and they will no longer lose their strength.

conclusions

Titanium is a modern high-tech material from which dentures and implants of any complexity are successfully manufactured.

They have a number of advantages, including harmlessness to the patient’s health, high survival rate and durability.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags implantation

Did you like the article? stay tuned

Previous article

How does the effective and painless method of photodynamic therapy in dentistry work?

Next article

Memo to the patient after dental implantation or how to prevent complications